What Is The Polythene Recycling Process?

In today's environmentally conscious world, the topic of recycling polyethylene plastic and its necessity has gained prominence. Derived from crude oil, polythene is widely used due to its numerous benefits. However, the low recycling rate for this type of plastic is concerning, primarily due to the lack of recycling facilities and challenges in sorting and processing.

This article explores the polythene recycling process, emphasizing the importance of active participation from businesses and individuals. By understanding the steps involved and the potential for reducing the consumption of raw materials, we can promote a greener future.

What is the Overall Plastic Recycling Process?

The overall plastic recycling process involves the collection, sorting, reprocessing, and transformation of plastic waste into new products.

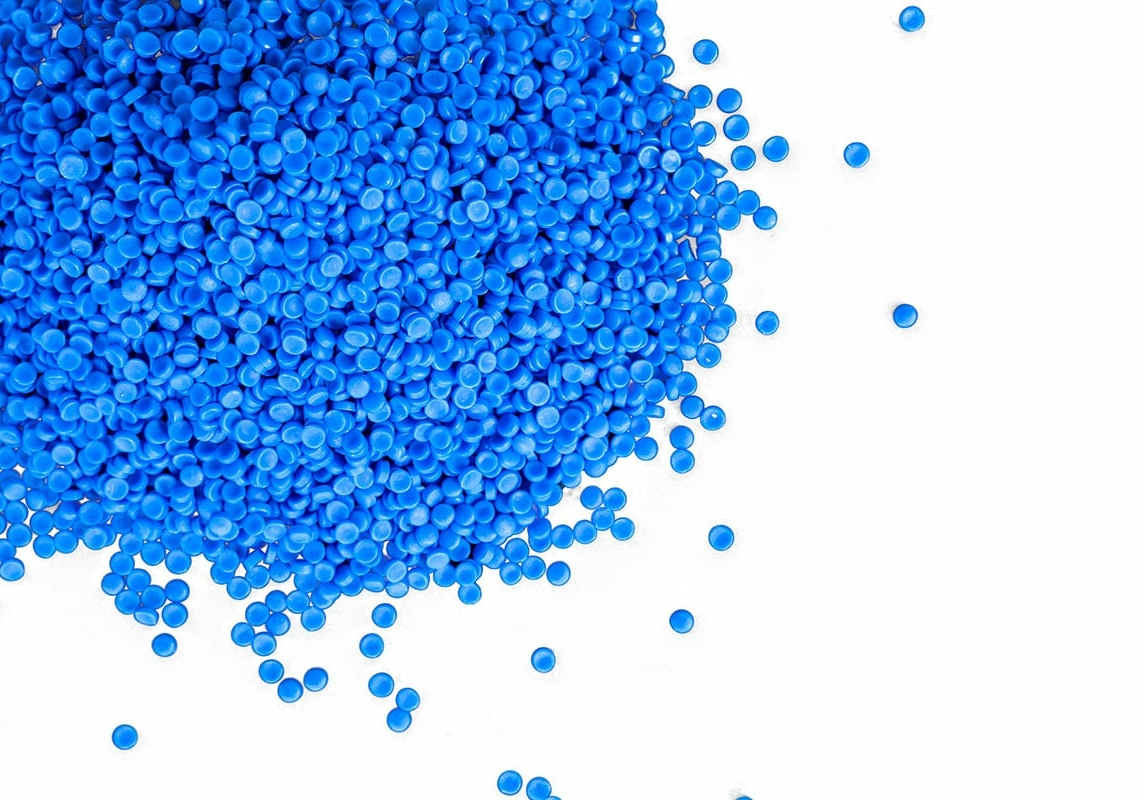

When it comes to polythene bags recycling, the process begins with the collection of used polythene bags from consumers. These bags are then sorted based on their type and colour to ensure proper recycling. The next step is shredding the polythene bags to remove any debris and contaminants. Cleaning the plastic is also necessary to maintain its properties. Once cleaned, the plastic is melted and transformed into uniform pellets, which can be purchased by plastic manufacturers to make new products.

This process of recycling polythene bags helps to reduce waste and conserve resources, making it an important step in the overall plastic recycling process.

What Are The Different Types Of Polythene Plastics

There are three main types of polythene: High-Density Polythene (HDPE), Low-Density Polythene (LDPE), and Linear Low-Density Polythene (LLDPE).

- HDPE is known for its durability and sturdiness, making it commonly used in plastic packaging, containers, and piping.

- LDPE, on the other hand, has properties like strength-to-weight ratio and water resistance, making it ideal for various applications. LDPE objects can be recycled into a generic material for creating new items.

- LLDPE is a blend of HDPE and LDPE, offering a balance of strength and flexibility.

All three types of polythene can theoretically be recycled, but HDPE and LDPE are more challenging to recycle compared to other plastics. However, with the right recycling processes and facilities, it is possible to recycle polythene and reduce the consumption of raw materials and oils.

What Can Polymac Do For You

Polymac packaging, has a licence to carry waste, this allows us to offer a range of services to assist businesses in recycling their unused plastics. Our goal is to provide a convenient and sustainable solution for polythene waste management.

We offer a free collection service for existing customers, ensuring that your unused polythene is properly disposed of and recycled. By partnering with trusted recycling centres, we ensure that the polythene is processed responsibly through the polythene plastic recycling process, where it is sorted, cleaned, and melted to create high-quality recycled polythene pellets, resulting in high-quality packaging solutions sold here at Polymac. We understand certain industries such as the medical field for example require vigin plastics. However, we aim to reduce the amount of unnecessary virgin bags that are used as this uses far more energy than re-used polythene. With our services, you can contribute to a more sustainable future by effectively recycling your polythene waste and reducing your business's carbon footprint.

Contact us today to learn more about how we can assist you in recycling polythene and revolutionise your waste processes.

Why Recycling Is Important

Recycling is a crucial practice that helps preserve the environment and conserve valuable resources for future generations. It is important to recycle polythene plastic because it reduces waste and conserves resources.

By recycling polythene, we can reduce the need for virgin plastic production and minimise the environmental impact of plastic waste. Polythene, specifically low-density polyethene (LDPE), is recyclable and can be transformed into various products such as plastic lumber and garden furniture.

However, the recycling rate for polythene is relatively low compared to other plastics. Increasing the recycling of polythene can help reduce pollution, save energy, and protect natural resources.

Therefore, it is essential to promote and prioritise polythene plastic recycling to create a sustainable and eco-friendly future.

How Is Polythene Plastic Recycled?

Sorting Process

The initial stage in the recycling of polythene plastic involves the sorting process. Efficient sorting plays a crucial role in the success of polythene recycling, offering several benefits. Firstly, it allows for the separation of different types of polythene, such as High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE), which have unique properties and recycling requirements. Additionally, advancements in technology have greatly improved the sorting process, with the use of machines and optical sorting systems that can accurately identify and separate polythene materials based on their composition and colour. However, sorting different types of polythene can present challenges, as some forms are more difficult to recycle than others. Manual sorting is also an important aspect of the process, as it ensures the removal of contaminants and helps achieve a higher quality of recycled polythene. Effective sorting ultimately has a significant impact on the quality of the recycled polythene, allowing it to be transformed into new products with optimal performance and durability.

Reprocessing Process

Initiating the recycling process, polythene plastic undergoes a reprocessing procedure to transform it into usable materials. Reprocessing polythene presents several challenges, including the lack of recycling facilities and difficulties in sorting and processing the material. However, the benefits of recycling polythene are significant.

Recycling polythene helps in effective waste management, reducing the environmental impact of plastic waste. It reduces the consumption of raw materials and oils, conserving valuable resources. The reprocessing process involves sorting the plastic, shredding it into small chunks, cleaning it to remove contaminants, and finally melting and compressing it into uniform pellets. These pellets can then be sold as raw inputs to plastic manufacturers such as ourselves, enabling the creation of new plastic products such as our polythene bags & lay flat tubing. Which we are proud to say are made from 30% recycled material, allowing us to offer Green and Renewable Polythene Packaging.

Our Polythene Bags are made from 30% recycled materials

Through the processes described above, Polymac's Polythene Bags

are made from 30% recycled materials.

What Are The Advantages Of Using Polythene As Packaging Material?

The utilisation of polythene as a packaging material offers numerous advantages in terms of sustainability and functionality. One of the key benefits is that polythene is completely recyclable and can be recycled multiple times. This means that it can be transformed into new products such as recycled polythene bags, reducing the need for virgin plastic production.

Additionally, polythene is a type of plastic that is relatively easy to recycle, including high-density polyethene (HDPE) and low-density polyethene (LDPE). There are polyethene recyclers available that can process these materials.

Moreover, polythene offers a lightweight and durable packaging solution, reducing the weight and cost of transportation compared to paper packaging. For more information click here to find out more about polythene packaging benefits.

Conclusion

In conclusion, the polythene plastic recycling process is crucial for reducing the consumption of raw materials and oils, while also promoting the creation of new products. By understanding the steps involved in sorting, shredding, cleaning, and melting, we can actively participate in recycling efforts and contribute to a more environmentally conscious world.

Proper identification and sorting of different types of polythene are also important to ensure effective recycling.

Get your quote today

call us on 01384 892 441

Get in touch below or give our experts a call on 01384 892 441 from simple questions to ordering bespoke packaging, we’re always happy to help.